As stated in the introduction, this tutorial uses the Turbofan engine degradation simulation data set to simulate data from a set of airplane engines for training and testing. In our experimental scenario, we know that: The data consists of multiple multivariate time series. Each data set is divided into training and test subsets. By converting our sims to HTML5, we make them seamlessly available across platforms and devices. Whether you have laptops, iPads, chromebooks, or BYOD, your favorite PhET sims are always right at your fingertips.Become part of our mission today, and transform the learning experiences of students everywhere!

- Engine Sim Test Machine Amazon

- Engine Sim Test Machine Walgreens

- Engine Sim Test Machine Procedure

- Engine Sim Test Machine For Sale

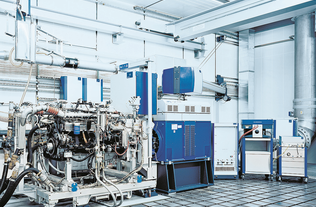

Or just try out the fully functional simulation of an internal combustion engine with control modules, sensors, actuators and CAN network. Use the oscilloscope, diagnostic system, break-out box and other tools to measure and read out the system. Disconnect, remove and replace components and wires to fix problems. Try out the Electude Simulator. SuperFlow manufactures water brake, eddy current and AC engine dynamometers for performance and industrial applications. SuperFlow engine dynos test gasoline, diesel and CNG engines and several of our water brake dynos are used for AC motor testing. We frequently provide custom engineered solutions for unique test requirements. Our engineering team will understand the application, select the.

Ground Support Test Equipment

Other Services & Offers : Adaptive services / Warranty Registration/ Distribution / Calibration Services /NexGen Proactive Test Equipment

Industry Leading Manufacturer

Thanks to 65 years of expertise and highly qualified engineers and technicians, Barfield has developed highly reliable, user-friendly test equipment at competitive market prices.

Barfield has become a recognized worldwide market leader in GSTE, which provides quality products, dedicated technical product support and excellent customer service. A wide range of aircraft specific field quantity adapter assemblies, cables, and modules are also manufactured as part of Barfield’s product lines.

Major product lines:

- Air Data/Pitot Static, RVSM Air Data tester -Check out our video

- Cable tensiometer tester

- Fuel quantity tester

- Turbine temperature tester

- Miscellaneous testers - Sight Compass, Megohmmeter, Pressure

We also distribute the following aircraft test equipment:

- Airbus Engineering Avionics Products

- NDT - Fluke

- Pitot/Static adapters - NAVAIDS LTD

- Bird

- Fluke

- Universal Synaptics

Our Calibration Services

Through the use of various standards and processes, Barfield is constantly striving to guarantee a high level of quality and flight safety. We pay attention to what our customers are saying and often work with them to achieve decreased maintenance through our product reliability program.

- Calibration Services for Ground Support Test Equipment

- Quality Program

- Technical Resources

Contact

Phone: +1 305 894 5454

Email: gste.service@barfieldinc.com

An Air Data Test Set performs two basic functions:

- Provides the means to leak test an aircraft's Pitot-Static system

- Simulates pressure and vacuum conditions required to calibrate the airspeed, altimeter, vertical speed, manifold pressure, and engine pressure ratio (EPR) indicators.

Barfield has been manufacturing analog, digital, and RVSM Pitot Static/Air Data test sets for over 40 years. All Barfield Pitot-Static testers (Analog and Digital) are designed to meet or exceed the requirements of DOT Advisory Circular 43-203B for performing altimeter and static system tests and inspections. In addition, Barfield offers a full line of high accuracy Air Data testers (Models DPSXXX) meeting or exceeding the Aircraft OEM’s most demanding RVSM accuracy requirements. Barfield also offers the entire Nav-Aids product line of custom Pitot tube and static port adapters for most Military, Helicopter, General Aviation, Corporate Jets, and Airlines.

Barfield RVSM Testers - DPS1000

The DPS1000 is replacing the successful DPS350 as our low cost flight line air data test set.

The DPS1000 is Barfield’s latest fully automated, user-friendly RVSM compliant air data test set. The DPS1000 performs altimeter and static systems tests and inspections. Critical components used in the DPS1000 have a well established history of proven flight line accuracy including pumps, valves and static/altitude transducers.

- Brochure >

- Automated Pitot/Static &

Air Data Test Set Specifications > - Air Data Feature Chart >

- Instruction Manual >

- Download the Field Firmware Update Procedure >

- Software Downloads >

- Get the apps:

Barfield Pitot-Static Testers - 1811NG

The newly introduced 1811NG is the first fully automated pitot static tester directly supporting General Aviation, Helicopter, UAV, Non-RVSM Regional and Corporate aircraft. Critical components used in the 1811NG have well-established history of provem flight line reliability & accuracy - including case, pumps, valves, and pressure transducers.

In 2013, Barfield introduced a new and innovative feature to the 1811NG sister product the DPS1000: a first of its kind wireless tablet communication capability allowing display and control using the latest Wi-Fi technology. This wireless Wi-Fi technology is being carried through to the newest Imperium series product the 1811NG.

- Brochure >

- Automated Pitot/Static &

Air Data Test Set Specifications > - Air Data Feature Chart >

- Instruction Manual >

- Download the Field Firmware Update Procedure >

- Software Downloads >

- Get the apps:

Barfield PitotStatic Testers - 1811D

The Barfield 1811D is an inexpensive, portable, self-contained field tester. It is ideal for leak testing aircraft pitot and static systems or on-board testing of altimeters and airspeed indicators.

The tester uses two analog or digital instruments (Altimeter and Airspeed) to perform aircraft leak tests or instrument calibration checks. All legacy 1811 series testers are configured with hand pumps and external pressure ports for supplying the necessary pressure and vacuum needed for on-board testing.

The Barfield 1811 series pitot/static testers are very practical for new facilities or those with a limited budget. The unit includes two 25-ft. hoses, a pitot mast adapter, and a 2423F static port adapter kit.

The following is a list of available configurations.

- 1811D405 (60-420kts, 35k ft.) analog instruments

- 1811D605 (20-250kts, 35k ft.) analog instruments

- 1811D403 (60-420kts, 50k ft.) analog instruments

- 1811D603 (20-250kts, 50k ft.) analog instruments

- 1811DA0A (20-650kts, 55k ft.) digital instruments

Digital instruments do not require correction cards.

- Brochure >

- Instruction Manual >

Barfield PitotStatic Testers - 1811GA

The Barfield 1811GA testers are portable, selfcontained units, used for testing and calibrating aircraft pitot-static systems. The tester has three instruments capability for analog (Altimeter, Vertical Speed, and Airspeed) units or two digital instruments to perform aircraft leak tests or instrument calibrations.

All legacy 1811 series testers are configured with hand pumps and external pressure ports for supplying the necessary pressure and vacuum needed for on-board testing and calibration. The Barfield 1811 series of Air Data testers are practical for new facilities or for those with a limited budget. The unit includes two 25-ft hoses, a pitot mast adapter, a 2423F static port adapter kit and a pitot-static system cd-rom.

The following is a list of common configurations.

- 1811GA425 (60-420kts, 2k ft/min, 35k ft.) analog

- 1811GA435 (60-420kts, 3k ft/min, 35k ft.) analog

- 1811GA445 (60-420kts, 4k ft/min, 35k ft.) analog

- 1811GA465 (60-420kts, 6k ft/min, 35k ft.) analog

- 1811GA625 (20-250kts, 2k ft/min, 35k ft.) analog

- 1811GA635 (20-250kts, 3k ft/min, 35k ft.) analog

- 1811GA645 (20-250kts, 4k ft/min, 35k ft.) analog

- 1811GA665 (20-250kts, 6k ft/min, 35k ft.) analog

- 1811GA423 (60-420kts, 2k ft/min, 50k ft.) analog

- 1811GA433 (60-420kts, 3k ft/min, 50k ft.) analog

- 1811GA443 (60-420kts, 4k ft/min, 50k ft.) analog

- 1811GA463 (60-420kts, 6k ft/min, 50k ft.) analog

- 1811GAAOA (20-650kts, 6k ft/min, 55k ft.) digital

Digital instruments do not require correction cards.

- Brochure >

- Instruction Manual >

Barfield PitotStatic Testers - 1811HA

The Barfield 1811HA testers are portable, selfcontained units, used for testing and calibrating aircraft pitot-static systems. The tester has threeinstrument capability for analog (Altimeter, Vertical Speed, and Airspeed) units to perform aircraft leak tests or instrument calibrations.

All 1811 series testers are configured with hand pumps and external pressure ports for supplying the necessary pressure and vacuum needed for on-board testing and calibration. 1811HA models come with an additional internal electric pump.

The legacy Barfield 1811 series of Air Data testers are practical for new facilities or for those with a limited budget. The unit includes two 25-ft hoses, a pitot mast adapter, a 2423F static port adapter kit and a pitot-static system cd-rom.

The following is a list of common configurations.

- 1811HA425 (60-420kts, 2k ft/min, 35k ft.) analog

- 1811HA435 (60-420kts, 3k ft/min, 35k ft.) analog

- 1811HA445 (60-420kts, 4k ft/min, 35k ft.) analog

- 1811HA465 (60-420kts, 6k ft/min, 35k ft.) analog

- 1811HA625 (20-250kts, 2k ft/min, 35k ft.) analog

- 1811HA635 (20-250kts, 3k ft/min, 35k ft.) analog

- 1811HA645 (20-250kts, 4k ft/min, 35k ft.) analog

- 1811HA665 (20-250kts, 6k ft/min, 35k ft.) analog

- 1811HA423 (60-420kts, 2k ft/min, 50k ft.) analog

- 1811HA433 (60-420kts, 3k ft/min, 50k ft.) analog

- 1811HA443 (60-420kts, 4k ft/min, 50k ft.) analog

- 1811HA463 (60-420kts, 6k ft/min, 50k ft.) analog

- 1811HAAOA (20-650kts, 6k ft/min, 55k ft.) digital

Digital instruments do not require correction cards.

- Brochure >

- Instruction Manual >

Barfield RVSM Testers - DPS501 NG Air Data Test Set

The DPS501 is Barfield’s latest high accuracy air data management system test set. The DPS501 NG is capable of controlling and measuring Altitude and Airspeed pressures to the highest degree of accuracy. The control and measurement range of the test system meets or exceeds most requirements for commercial and military test applications. In addition, the DPS501 NG complies with requirements for RVSM.

The DPS501 NG software provides a familiar and intuitive graphical user interface. Modes of Operation are easily selected through tabs located along the top of the screen. The operator can easily switch between modes while testing without affecting operation.The calibrator measures and records readings, while displaying data as a table or graphically. All information is stored directly on the calibrator and reports can be printed. The DPS501 NG can be operated remotely using the RS-232 (serial) port on the rear panel. The operating platform allows the system to be upgraded for future test applications through software upgrades, standalone installer packages or customized software applications.

- Brochure >

Barfield Digital Instruments - DALT55 & DAS650

The aviation industry has an enormous need for more reliable and cost effective tools for performing standard pitot-static system leak tests, FAR 91-411 and/or FAR 43 Appendix E certifications. These needs motivated Barfield to design and produce digital replacement instruments for the Barfield 1811 series and equivalent testers.

The DALT55 Digital Altimeter and the DAS650 Digital Airspeed indicator were designed to be a direct replacement to the current analog instruments. Being of similar shape and size of existing analog instruments, the new digital version fits all Barfield 1811 series and most other manufacturers of analog pitot-static test sets.

Standard analog instruments provided in a Barfield 1811 series or equivalent pitot-static tester are delicate mechanical devices easily damaged or destroyed by inexperienced or distracted technicians. The DALT55 and DAS650 use state-of- the-art transducer technology for pressure measurements making them virtually immune to the frequent and costly repairs generally associated with analog instruments.

- Brochure >

- Instruction Manual DALT55 >

- Instruction Manual DAS650 >

Accessories NAV-Aids Ltd - nav

Pre-Test Probes

The pre-testers are employed to verify the integrity of the pitot test adapter, hoses and air data test set prior to connection to the aircraft. The probe is inserted into the pitot test adapter while connected to the hose and air data test set. By applying pneumatic pressure, the entire assembly (tester, hoses & adapters) are checked for leakage.

Pitot Test Adapters

The pitot test adapter body is of solid uni-body construction. There is no metal to metal contact between pitot tube and test adapters. Seals and spacers inside the adapter body ensure a leak free connection. They are easily exchanged without special tools. Optional high temperature seals and spacers can be installed upon request.

Static Test Adapters

Static test adapters provide a connecting seal at the aircraft’s static ports. The means of attachment depend on the aircraft type. Installation and removal of our adapters takes just a few seconds.

Air Data Accessory Kits

Air data accessory kits contain all the required test adapters and hoses to connect the air data test set to the aircraft type for which the kit is designed. Also included as standard equipment are pre-test adapters, seal kits and lubrication fluid. Depending on the need, additional equipment such as control consoles and suspension arms are a part of the kit. RVSM Air data accessory kits are available.

- Brochure >

Barfield RVSM Testers - DPS500 NG

The DPS500NG is Barfield’s latest fully automated, intuitive RVSM compliant air data test set. The DPS500NG is a portable, high precision, dual channel air data pressure test system. This tester is designed to calibrate, test and troubleshoot air data instrumentation and aircraft pitot-static systems. The test set has been designed with functional and reliability features highly suited to withstand the harsh environmental and demanding conditions of the flight line environment. The test set is designed for testing a wide range of commercial and military aircraft, both rotary and fixed wing. Designed with both hardware and software safety features, the DPS500NG provides maximum protection for the test set and the Unit Under Test (UUT). These features include over-range, overlimit, and over-pressurization protection, micro-porous filters, pressure relief valves, UUT isolation in the event of a power failure and more

Brochure >

Fuel capacitance systems are separated into two broad groupings, AC capacitance and DC capacitance. The source of these names derives from the type of signal processed by the fuel system amplifier. Barfield designs a universal tester for each type of system with the proper interface harnesses to access individual aircraft applications. Some of the various test and measurements include:

- Insulation - Testing the wiring and probes

- Fuel Tank Capacitance Measurement

- Individual Probe Capacitance Measurement

- Capacitance Simulation - Indicators and amplifiers

- Indicators - Bench testing of remote units

Contrary to popular belief, there is no 'black magic' in troubleshooting and calibrating fuel capacitance systems, but only if you have the right equipment!

Fuel quantity testers - DC400A

The compact and lightweight DC400A is a complete fuel quantity system test set for use on aircraft that have probes with integral diode rectification, commonly called “DC” fuel quantity systems.

The DC-400A is a completely self-contained, portable, lightweight, internal battery powered DC fuel quantity system Test Set. The tester is specifically designed, when used with the proper Adapter Module, to meet the requirements for testing and calibration of a wide range of Aircraft DC Fuel Quantity Systems.

The DC400A has been engineered to provide the technician the following capabilities: Capability to bench check Aircraft fuel quantity system components.

Capability to test all major components and circuitry in the Aircraft’s DC fuel quantity system. Provides direct digital LCD readout of probe capacitance.

Digital readout of quantity system output in (volts, lb., ratio, etc.).

Maximum ease of operation and maintenance.

- Brochure >

- Instruction Manual >

- Adapter Module 1 >User instruction supplement M/N DC400/A - P/N 101-00802

- Adapter Module 2 > User instruction supplement M/N DC400/A - P/N 101-00802

Fuel quantity testers - DFQ40K

The DFQ40K is designed for and is compatible with all aircraft, which have AC capacitance, based Fuel Quantity Indicating Systems including those equipped with transient suppressors.

The DFQ40K has the ability to measure the insulation breakdown of tank units, wiring and connectors associated with the system, capacitance of the tank units which measure the level of fuel in the tanks and simulation of capacitances required to test and calibrate the aircraft indicating system. In addition to performing the standard capacitance tests of the Tank(s) and or Compensator, the DFQ40K has an additional troubleshooting mode that will provide the user with a relative indication of a problem associated with the Phase of the return current like that provided by the Barfield 2548H tester. The DFQ40K measures Low Resistances, DC Voltage & Indicator Drive Current. The DFQ40K is also equipped to measure the Distance To Fault to localize problems with the HIZ coax, continuity of the Shield Monitor, if the aircraft is so equipped, and Bonding tests to 0.001 Ohm resolution.

With the incorporation of the BACK, NEXT, MODE and RANGE pushbuttons to the panel membrane, switching the overall number of different screens, such as sub-menus to be displayed, is greatly reduced. This will simplify the screens and make it easier for the operator to learn and navigate. This also makes it possible to remove all pre-defined FUNCTION pushbuttons and embed those functions into the Soft Function key selection scheme.

- Brochure >

- Instruction manual >

Fuel quantity testers - 8000

NO LONGER PROCURABLE

- Replaced by DFQ40K

- Instruction Manual >

Fuel quantity testers - AC2K

NO LONGER PROCURABLE

- Replaced by DFQ40K

- Instruction Manual >

Fuel quantity testers - 2548H

NO LONGER PROCURABLE

- Replaced by DFQ40K

- Instruction Manual >

Barfield has been manufacturing Turbine Temperature Indicating System Test Sets for more than 40 years, and has amassed a vast knowledge of the common thermocouple EGT systems.

All Turbine Temperature test sets offered by Barfield meet the requirements for testing aircraft Type K (Chromel - Alumel) thermocouple systems and are capable of conducting the following tests:

- System Resistance and Insulation Testing

- Thermocouple Resistance

- Thermocouple Output Simulation for Indicator Accuracy Test

A typical aircraft Exhaust Gas Temperature (EGT) system consists of between 4-16 Type K (Chromel - Alumel) thermocouples, which are mounted parallel to each other. As the temperature increases in the engine exhaust, a voltage is induced in the thermocouple. Since the thermocouples are also electrically connected in parallel, the individual thermocouple voltages are averaged together to get a more precise voltage output and temperature indication. The voltages induced in a thermocouple are very small 40microvolts/degree (40uV/degree) and require very precise test equipment.

Turbine Temperature testers - TT1000A

The TT1000A is a completely self-contained, battery powered, aircraft turbine temperature system tester capable of measuring system lead resistance, insulation, and performing indicator run-outs with a range up to1000 °C. The unit was specifically designed to meet all requirements for testing aircraft Chromel/Alumel (CH/AL) turbine temperature measuring systems and provides an accurate display of thermocouple outputs in degrees Celsius (°C).

The TT1000A is engineered for maximum ease of operation and includes an automatic digital display that practically eliminates human error and reduces testing time to a minimum. The test leads incorporate automatic temperature compensation to remove induced voltage caused by a “Cold Junction” created when the test leads are attached to the aircraft.

All of the features designed into the TT1000A have been added to reduce maintenance time and cost as well as provide a maintenance friendly tester for measuring and displaying resistance of thermocouple, thermocouple rings and system lead circuits.

- Brochure >

- Instruction Manual >

Turbine Temperature testers - TT1200A

The Barfield TT1200A is our latest Digital Turbine Temperature Test Set. It is microprocessor based, completely self-contained, battery powered unit housed in a new high visibility ruggedized enclosure. It is designed with sufficient accuracies and range to be able to test the newest digital and glass cockpit indicators with simple operation, direct reading, and multi-function versatility.

The TT1200A is specifically designed to accomplish all requirements for testing the aircraft Chromel/ Alumel (K type) turbine temperature measuring systems. The Test Set can measure resistances down to 0.001Ω, measure insulation up to 200MΩ, perform indicator run-outs with a resolution of .1°C or 1°C and a range of 1372°C. It can also display the equivalent °F or millivoltages and may be used as a master indicator.

The TT1200A exceeds all of the operational capabilities of the popular Barfield TT1000A. Many new features include: microprocessor based, backlit alphanumeric display, user prompts, °F and millivoltage display, temperature range to 1372°C, 4 resistance and 4 insulation ranges and power comes from common “C” batteries for all functions.

- Brochure >

- Instruction Manual >

Turbine Temperature testers - 2312G

- NO LONGER PROCURABLE

- Replaced by TT1000A or TT1200A

- Instruction Manual >

Turbine Temperature testers - TT1200

- NO LONGER PROCURABLE

- Replaced by TT1200A

- Instruction manual >

The CT12A Cable Tensiometer is the latest Ground Support Test Equipment manufactured by Barfield. Developed in cooperation with a major aircraft OEM, the Barfield CT12A Cable Tensiometer has been engineered to comply with new specifications.

Used by OEMs, MROs and operators, the CT12A provides highly accurate and precise readings over a wide range of cable sizes. Barfield has combined technology with hand held ease in this vital tool used during cable rigging and routine tension measurements for all aircraft types.

Cable tensiometer tester - CT12A

The Barfield CT12A Digital Cable Tensiometer was designed to meet the industry’s requirements for testing and measuring the tension of aircraft cables. The CT12A measures the existing tension in 1/16” to 1/4” cables. Two different unit types are available within the product line: multi-cable and single-cable. Multi-cable units can measure up to seven different cable sizes; whereas single-cable units are customized for one specific cable size. The CT12A displays the battery life, last measured cable size, ambient temperature and cable tension.

The Barfield instrument allows users to perform an entire testing operation with one hand and without the use of conversion tables. Measurements are taken once the proper cable size is selected and when the tool is clamped onto the cable. The instrument’s display then shows the resulting measurement.

Both the multi-cable and single-cable units feature two modes of cable tension measurement: Standard Mode and Averaging Mode. Standard Mode gives individual cable tension measurements. Averaging Mode automatically averages three measurements.

- Brochure >

- Instruction Manual >

Barfield has maintained its leadership in the aviation industry by manufacturing an excellent line of products in addition to Pitot/Static, Fuel Quantity, and Turbine Temperature testers. Our miscellaneous category includes a wide range of other testers designed to meet today's specific aviation industry needs. These testers include pressure testing, backup compass testing and Automatic Test Equipment (ATE) for component maintenance. These test platforms are very reliable and combine state-of-the-art technical concepts with the latest philosophical requirements in the industry.

Miscellaneous testers - 2311FA

The 2311FA Pressure Tester field tests aircraft pressure systems for both reciprocating and turbine engine pressure systems. It provides pressure for testing pressure transmitters, warning switches pressure-type torque (BMEP) indicators and system leak testing in the range of 0-600 PSI.

The use of VITON (Fluro-carbon) seals on the piston permits the use of any fuel, lubricating or hydraulic fluid. The principal NON-COMPATIBLE fluids NOT to be used with VITON seals are: alcohol, aldehydes, amines, alkyl phosphate esters (skydrol), ethers and ketones.

- Brochure >

- Instruction manual >

Miscellaneous testers - SC063

The SC063 is a portable, self-contained calibration device used to check the mounted aircraft compass. Consisting of a modified aircraft compass which has been re-screened to indicate 180 degrees from normal. The SC063 allows the operator to stand facing the aircraft, making it considerably easier to transmit signals to and from the aircraft cockpit. The SC063 is unique in that the compensating magnets have been removed and a combination magnifying lens and collimating sight added.

The sight compass is painted orange and a caution label is attached to prevent inadvertent installation in an aircraft. Each unit is painted orange for clear identification and must not, under any circumstances, be used as an aircraft compass

- Brochure >

- Instruction Manual >

Miscellaneous testers - 2471F

NO LONGER PROCURABLE

- Brochure >

- Instruction Manual >

Below is a list of the User Instruction Manuals for Barfield's Test Sets. The Instruction/Operation Manuals are sorted alphabetically, first by product type, then by Model number.

AC Fuel Quantity Test Set

Model: 8000

Barfield P/N: 101-00540

Doc. No. - Rev.:56-101-00540-B

Latest Update: Nov/07/14

DC Fuel Quantity Test Set

Model: DC400A

Barfield P/N: 101-00850

Doc. No. - Rev.: 56-101-00850-C

Latest Update: Nov/07/14

Digital Air Data Tester

Model: DPS500

Barfield P/N: 101-01190

Doc. No.: 56-101-01190_01191-C

Latest Update: Nov/07/14

Digital Dual Channel Control

Model: DPS501

Barfield P/N: 101-01191

Doc. No. - Rev.: 56-101-01190_01191-C

Latest Update: Nov/07/14

Digital Cable Tensiometer

Model: CT12A

BarfieldP/N: 101-03100

Doc. No. - Rev.: 56-101-03100-G

Latest Update: Mar/06/15

Digital Fuel Quantity Tester

Model: AC2K

BarfieldP/N: 101-01401

Doc. No. - Rev.: 56-101-01401-B

Latest Update: Nov/17/14

Digital Pitot-Static Test Set

Model: DPS350

BarfieldP/N: 101-01170

Doc. No. -Rev.: 56-101-01170-F

Latest Update: Nov/07/14

Digital Pitot-Static Test Set

Model: DPS400

BarfieldP/N: 101-01180 (Prior to Mod. P)

Doc. No. - Rev.: 56-101-01180-B1

Latest Update: Jan/07/10

Digital Pitot-Static Test Set

Model: DPS400

BarfieldP/N: 101-01180 (Mod. P and later)

Doc. No. - Rev.: 56-101-01180-D

Latest Update: Jan/19/10

Fuel Quantity Test Set

Model: 2548H

BarfieldP/N: 101-00420

Doc. No. - Rev.: 56-101-00420-C

Latest Update: Nov/07/14

Fuel Quantity Test Set

Model: DFQ40K

BarfieldP/N: 101-01501/01502

Doc. No. - Rev.: 56-101-01501_01502-C

Latest Update: Nov/07/14

Megohmmeter

Model: 2471F

Barfield P/N: 101-00220

Doc. No. - Rev.: 56-101-00220-C

Latest Update: Nov/07/14

Pitot-Static Test Set

Model: 1811D

Barfield P/N: 101-00164

Engine Sim Test Machine Amazon

Doc. No. - Rev.: 56-101-00164-G

Latest Update: Nov/07/14

Pitot-Static Test Set

Model: 1811HA

Barfield P/N: 101-00184

Doc. No. - Rev.: 56-101-00184_00185-I

Latest Update: Sep/24/14

Pitot-Static Test Set

Model: 1811GA

Engine Sim Test Machine Walgreens

Barfield P/N: 101-00185

Doc. No. - Rev.: 56-101-00184_00185-I

Latest Update: Sep/24/14

Pitot-Static Test Set 1811NG

Model: 1811NG

Barfield P/N: 101-01178

Doc. No. - Rev.: 56-101-01178-K

Latest Update: September/02/20

Pitot-Static Test Set DPS1000

Model: DPS1000

Barfield P/N: 101-01175

Doc. No. - Rev.: 56-101-01175-L

Latest Update: September/02/20

Pressure Tester

Model: 2311FA

Barfield P/N: 101-00212

Doc. No. - Rev.:56-101-00212-D

Latest Update: Sep/16/14

Sight Compass

Model: SC063

Barfield P/N: 101-01200

Doc. No. - Rev.:56-101-01200-E

Latest Update: Nov/07/14

Turbine Temperature Test Set

Model: 2312G

Barfield P/N: 101-00550

Doc. No. - Rev.: 56-101-00550-D

Latest Update: Nov/07/14

Turbine Temperature Test Set

Model: TT1000A

Barfield P/N: 101-01901

Doc. No. - Rev.: 56-101-00901-E

Latest Update: Sep/19/14

Turbine Temperature Test Set

Model: TT1200

Barfield P/N: 101-00920

Doc. No. - Rev.: 56-101-00920-D

Latest Update: Nov/07/14

Turbine Temperature Test Set

Model: TT1200A

Barfield P/N: 101-00930

Doc. No. - Rev.:56-101-00930-F

Latest Update: Sep/25/14

Digital Altimeter Instrument

Model: DALT55

Barfield P/N: 101-02184

Doc. No. - Rev.: 61-101-02184_02186-E

Latest Update: Jun/25/15

Digital Airspeed Instrument

Model: DAS650

Barfield P/N: 101-02194

Doc. No. - Rev.: 61-101-02194-H

Latest Update: Nov/07/14

Pitot-Static Test Set

Model: 1811G/H

Barfield P/N: 101-00165_00168_00169

Doc. No. - Rev.: 56-101-00165_00168_00169-C

Latest Update: Dec/09/14

Barfield is also a distributor for 6 Test Equipment manufacturers. In addition to the complementary testers from Tel-Instruments Electronics Corp. and accessories from Nav-Aids for its Air Data/Pitot static testers, Barfield also distributes.

Airbus Engineering Avionics Products testers - G5-5M0-319-0000

Main Landing Gear Wheel Tachometer Driving Tool

- Control the rotation direction of the motors

- Control the speed of the motors

- Check the RPM of the motors

- Unit is supplied eith 28VDC and protected by a 5A fuse

- Drive motor support drives landing gear tachometer generators means of drive shafts

Airbus Engineering Avionics Products testers - G5-5M0-321-0000

Check Doors Tool

- Adjustment of Eldec proximity detector for FAR and NEAR configurations

- Check PETERCEM proximity detectors

- Self dependent by means of 18VC power supply

- Check of cargo compartment doors locked position indicating section

Airbus Engineering Avionics Products testers - G5-5M0-320-0300

28 VDC Power Supply Tool

- Activate side stick solenoid to enable the adjustment of transucer unit input lever

- Simulate auto pilot mode to check operation of spring rod in artificial feel unit

- Models available for A319, A320, A321

- Models available for A330, A340

- Models available for A340-500-600

Barfield values your opinion - You are invited to participate to our GSTE Sales survey:

Barfield values your opinion - You are invited to participate to our GSTE Services survey:

DIESEL-RK is an engine simulation tool

The DIESEL-RK is professional thermodynamic full-cycle engine simulation software. This tool covers wide range of practice tasks: from general multicylinder engine concept analysis up to design of engine systems. The kernel of DIESEL-RK includes gas-exchange model, heat-exchange in engine elements, turbocharging, EGR, friction, water condensation, etc. (everything for full cycle simulation). DIESEL-RK is focused on advanced diesel combustion simulation and on emission formation prediction. The main features of DIESEL-RK are below, see details in What is a Diesel-RK.pdf as well.

- Thermodynamic analysis of Diesels fuelled by diesel oil, methanol, bio-fuels and mixtures of bio fuels with diesel oil. HCCI / PCCI concepts and Dual fuel systems are supported.

- Thermodynamic analysis of SI petrol engines and gas engines, including prechamber engines, and engines fuelled by Natural gas (Methane), Pipeline gas (Propane-Butane), Biogas, Wood gas, Syngas with arbitrary composition (Producer gas), etc.

- Water injection with account of H2O condensation and evaporation in intake manifold, port, cylinder.

- Thermodynamic analysis of Two- and Four-stroke engines; Junkers OP engines; Crank case scavenged engines, etc.

- Simulation and optimization of Mixture Formation and Combustion in diesels.

- Fuel Injection optimization. Optimization of sprayer design and location. Optimization of injection pressure, injection timing, injection rate shaping, split / multiple injection strategy. Individual diameters and arbitrary orientation of each nozzle are supported.

- PCCI analysis including Low Temperature Combustion phase, etc.

- Few injectors in one cylinder may have independent control (own fuel and own injection profiles). This system may be optimized.

- Detail Chemistry is simulated for Ignition Delay prediction at PCCI and HCCI for Diesel Fuel, Methanol and for Bio-Fuel.

- Common Rail control algorithm development; Automatic optimization of Injection Profile flanks shape. Optimization of boot-shaped Injection Profile, Optimization of Sequential Injection Profiles.

- Effect of Combustion Chamber Geometry modification.

- Effect of spatial and on-wall sprays intersection (overlap) on HRR is accounted.

- Fuel Sprays Evolution visualization: easy on a flat diagrams and with included 3D tool.

- Nitrogen Oxides, Soot and Particles formation simulation. Detail Kinetic Mechanism for NOx formation at massive EGR and multiple injection.

- Simulation of effects of Turbocharging, Intake and Exhaust Port flows, Bypasses, configuration of EGR system (with Venturi nozzle, cooler and blower). Simulation of water injection into engine.

- Valve and Port Timing optimization. VVA optimization with the dwell of the valves.

- Multiparametric optimization of engines parameters, Conjoint optimization of NOx, PM and SFC, including Pareto optimization.

- DIESEL-RK solver may be run under the control of other packages: Simulink, IOSO NM, etc.

- The tool is very easy in use. Remote access is provided (free for academic use). Download 4.3.0.189 version of Diesel-RK Client

Latest release: 5.3.9.78 (June 2020) has 3D mesh for sprays spatial intersection analysis; supports dual fuel engines, engines having few (up to 5) fuel injection systems working independently and injecting different fuels in one cycle; Finite Element Analysis of engine parts temperatures (What is a Diesel-RK.pdf).

Engine Sim Test Machine Procedure

| Select language to continue: | Bauman Moscow State Technical University (BMSTU). |

This project has been supported by EU Marie-Curie International Incoming Fellowship Grant FP7-PEOPLE-2012-IIF/PIIF-GA-2012-328361.

DIESEL-RK is a new generation of engine simulation software DIESEL intended for ICE analysis. Diesel-RK code allows simulation and optimization of mixture formation and combustion in diesel engines. Spatial visualization of fuel sprays evolution helps to design piston bowl shape and sprayer nozzles orientations. NO emission model uses Zeldovich's mechanism for conventional engines and Detailed Kinetic Mechanism with zone model of combustion for modern engines having large EGR and multiple injection. Soot emission model is realized. Modeling of combustion with multiple fuel injection with electronically controlled fuel injection system allows development a Common Rail control algorithm. Thermodynamic model provides turbocharger and supercharger matching using SAE format files with turbine and compressor maps, EGR and bypasses simulation. Thermodynamic analysis and multiparametric optimization of valve timing, in-cylinder parameters, fuel injection system are provided. Remote access via Internet is supported. For simultaneous optimization of few engine parameters: NOx, Soot and SFC the target function including list of engine parameters may be calculated with User Model DLL and linked to the existing DIESEL-RK kernel. Detail Chemistry simulation at Ignition delay prediction for diesel fuel and Bio-fuel is implemented for PCCI and HCCI analysis. Results obtained with CHEMKIN code are used. Gas engines fueled by any kind of gas including natural gas, pipeline gas, biogas, syngas and arbitrary mixtures of gases are supported. Download software for free ...

Engine Sim Test Machine For Sale